blanket machines

ALBAGRAF XT

- Machine that has been manufactured for high fibers (blanket) fabric printing by thermo drawing, showing the printed drawing under relief. With fabric compensating systems inlet and outlet of the machine to control fabric tensions. Fabric feeding with fan system to fold the fabric in trolleys.

- Fabric alignment system mounted in front, with photo cells and pneumatic cylindres, which are in charge of the fabric alignment before the drawing of the desing.

- The fabric route in the central part of the machine is done on the design pressing and drawing table. A temperature bench with automatic up and down movement is mounted on this table, we set the design to be drawn under it.

- System for heating the plates by using 42 resistances of 750V.

- Digital programmable screen for starting and stopping, temperature clock with adjustment from 0º to 250ºC, time of pressing programmation, etc.

- Adjustable speed by electronic variator from 5 to 22mtrs/minute. The useful measures for the fabric drawing are from 2.600mm width x 2.400mm length. They can be changed following the customer's needs.

- Safety systems following CE rules.

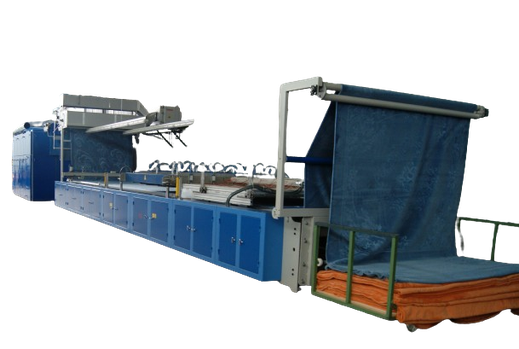

ALBAGRAF XT-ES

This machine has been designed for embossing and printing high and short fibers (blanket) fabric by thermo drawing, showing the printed drawing under relief.

It has conveyor belt and a fabric compensation system for entering and exiting the machine to control fabric tensions and a fabric feeding system with a fan to fold the fabric into carts. The machine includes a programmable digital display, safety devices and electrical panels to operate the machine.

The blanket is printed when the fabric enters the machine. Temperature adjustment is regulated through control panels, preset pressing time, etc. After that, the fabric is ready to be printed in the next step. This way, it is perfectly fixed by the frame and the printing spacers and, after passing through the oven, the blanket is ready.

The embossing, printing and drying of the blankets are done one after the other and we achieve fast, efficient and profitable production.

TIGRE TG07

- This machine has been specially designed to fray and brush the blankets fabric an excellent heighten and brushing can be obtained by using this machine, what gives a lot of volume to the final product.

- This fraying and brushing system works with several useful widht capacities, reaching until 3.200mm. The cylinder width is 3.400mm.

- This machine is equipped with a system to control the fabric tension and centring of this one.

- Our machine frays the blanket in only one passing, so it is very productive and competent. It also includes a fibers aspiration system so as to get the final fabric product in the best conditions.

- Control board with digital screen for machine operations which includes electronic speed variator that allows to control the fabric passage speed until 20mtrs/minute,

- It is also equipped with contact adjustement of the fabric with the cylinder for fraying and a counter of metres clock.

- All our machines follow the safety rules CE, and include Marked CE.

TUNDOSA

- Strong machine to avoid any kind of vibration, with high production capacity.

- Maximum height in fabric intake and outlay for big capacity trolleys.

- Automatic system to center the fabric.

- Seams detector with regulation for any kind of fabric thickness.

- Speed control from 5 to 22 mts/minute driven from the control board.

- Axial shearing cylinder movement.

- Pneumatic lifting of the shearing cylinder for frontal blade sharpeing.

- Fabric advance and tension by induction motors driven by vectorial inverter.

- Motorised shearing height with digital indicator.

- Contact in polished cylinder adjusted mechanically.

- Automatic seams detector with shearing and polishing tables movement.

- Control board with switches, push buttons of starting and stop, meters and control lights for all the operations.

- Machine equipped with all the safety systems following the international safety rules for the accidents prevention marked CE.